Aluminium surface finishing

Abbrasive Blasting/Brushing/Anodizing/Painting&Coating/Laser making

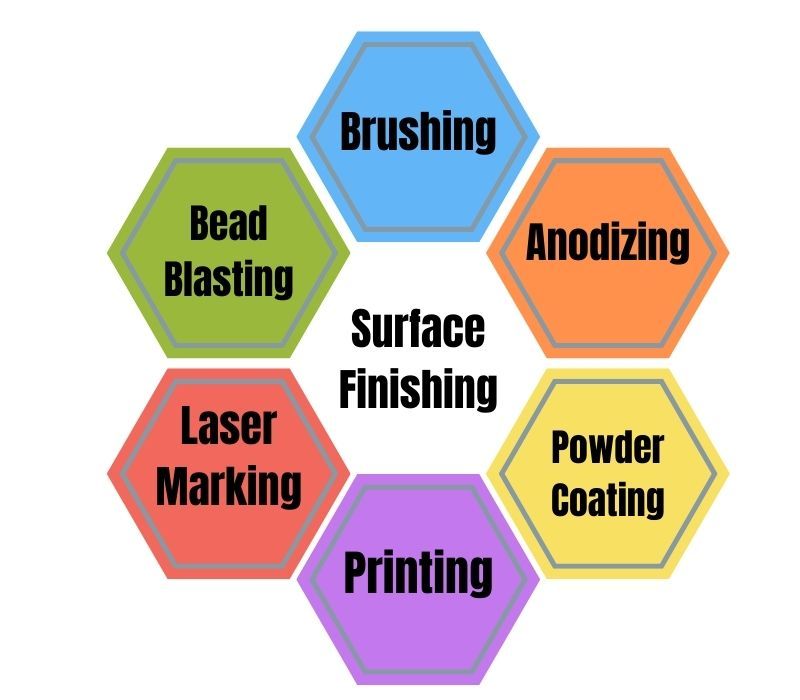

Surface finishing of aluminum is essential for most aluminum extrusion enclosures, heatsinks, panels, or brackets after the machining process is completed. We offer a variety of surface finishing options, including bead blasting, brushing, anodizing, powder coating, Silk printing, and laser marking. These methods provide different textures on the surface of aluminum alloy workpieces and are recommended to prevent rust and oxidation.

One of our strengths lies in our value-added surface finishing services. We manage the complex and intricate machining and finishing processes to deliver the best products to our clients.

Following the finishing process, we conduct thorough inspections to ensure that the surfaces are clean and free from defects. Our outsourcing partners are experts in their respective finishing fields, and we have been collaborating with them for over 10 years, striving to meet our clients' requirements.

- Abrasive Blasting

- Anodizing

- Brushing

- Powder Coating

- Laser Engraving And Screen Printing

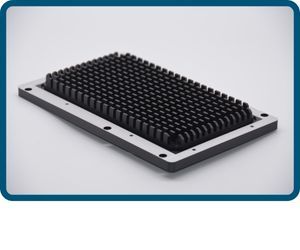

Abrasive blasting

The purpose of beat blasting, also known as abrasive blasting, is to smooth a rough surface of the work piece and to perform better quality both visually and tactually. Furthermore, it can perform better quality and metallic texture appearance with anodizing. We offer various roughness of sand blasting treatment depending on the requirement of our customers. Benefits of sand blasting is to remove burr or surface contaminants and to smoothen a rough surface. Also, different surface roughness is available to perform different textures. It is usually used as a pre processing for anodizing and powder coating work piece, improving adhesion and corrosion resistance of the work piece.

Anodizing

Anodizing is one of the most popular surface treatments used to increase the thickness of the natural oxide layer on the surface of aluminum parts. Most aluminum made embedded computer or fan less chassis are anodized because of the characteristic of its corrosion-resistant durability, color stability and aesthetic. In addition, it is the most efficient and low-cost solution with great value for surface treatment. Various color alternatives are available upon request, please feel free to contact for more information. In addition to traditional anodizing, we also offer hardcoat anodizing which provides a surface that is more wear resistant and has a smoother and harder finish. it is usually applied for aluminum workpieces that require hard wear resistance such as military used components and electrical resistivity.

Brushing

Brushed finish is one of the most popular pre-processing methods for aluminum in decorative uses. It is processed by brushing aluminum with an 80-1000 grit belt that gives aluminum a distinctive look with a metallic muted luster and a pattern of fine parallel line. It is commonly processed before anodizing to not only smoothen a dull surface but also produce an aesthetic look on the workpiece. Various texture and metallic luster effects can be presented with different abrasive belts from 80-1000.

Powder coating

Powder coating is usually used to create a hard finish which prevents aluminum from rusting and oxidized. The benefit of powder coating is that it will have fewer appearance differences compared to anodizing items. We provide liquid coating, powder coating and some effect coating using special paint such as metallic paint.

Laser engraving and Screen printing

We provide custom laser engraving service for aluminum workpieces. Using laser light to break the oxide layer on the surface of the workpiece to accurately and quickly engrave the designed graphics, numbers or fonts and partially. It has the superior quality of clear lines and permanently lasting on the workpiece. We also provide another common surface treatment method, which is screen printing. Painting the logos or patterns or icons on the workpiece. We offer custom colors and patterns depending on the needs of our customers.

- Related product

powder coating embedded chassis

Aluminum extrusion chassis processing by CNC and coating with antibacteria paint. Customize depends on the requirements.

DetailsBlue Powder Coating Aluminum Front Plate

Surface fininshing with powder coating in blue color. Customized made in various size. Tape adhesive in the back of the product is availible.

DetailsGold anodizedaluminum extrsion chassis

Gold anodized aluminum extrsion chassis. Custmized made according to the requirements.

DetailsRed assembled embedded chassis

The chassis can be disassembled into top cover, bottom plate, front and rear panels. Customize made exclusive chassis according to the requirments.

Details