Soldering Thermal Module

Thermal Module Manufacturing

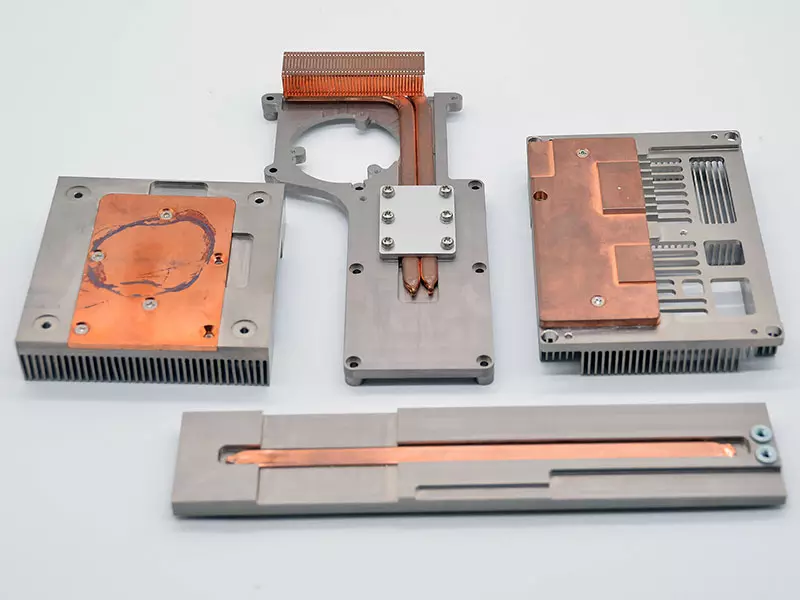

We offer different kind of thermal module heatsink depends on the need of customers. Soldering is used in thermal module for many years. Soldering provides good thermal conductivity and permanent connection between metal fins, plates, or heat pipes in thermal module or cooler. Wherever there is heat dissipation requirements, there will be thermal module needed.

aluminum extrusion thermal module

highly performance slodering thermal module for 3C products. Custom made upon request.

DetailsHaving trouble dealing with aluminum manufacturing?

Contact us and we will provide solutions.

More DetailsHow does soldering technology improve thermal conductivity in electronic cooling systems?

Soldering creates permanent metallurgical bonds between components in thermal modules, significantly enhancing heat transfer efficiency by eliminating air gaps and contact resistance. Our advanced soldering techniques for aluminum thermal modules achieve up to 40% better thermal conductivity compared to mechanical assembly methods, ensuring critical electronics remain within optimal temperature ranges even under heavy processing loads.

Each customized thermal module is precision-engineered to address specific cooling challenges across various applications. Our aluminum extrusion thermal modules combine excellent thermal properties with lightweight design, making them ideal for space-constrained electronics where effective heat management is critical. Whether you need standard heatsinks or complex cooling solutions with multiple heat pipes, Han Chang's manufacturing capabilities ensure optimal thermal performance, extended product lifespan, and reliable operation even in demanding environments.