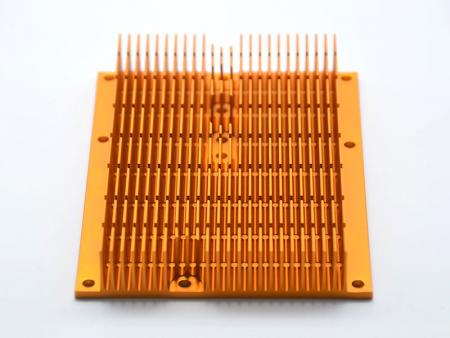

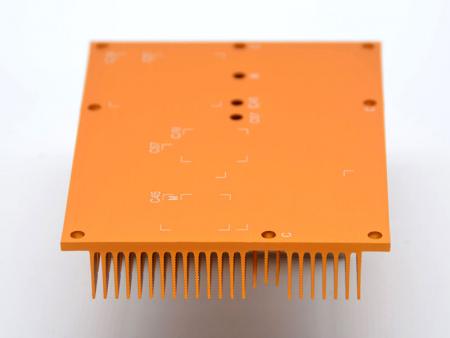

Anodided alumium extruded heatsink

Customize Heatsink in Various Dimension

aluminium extruded made by aluminium extrusion process. Customized lengths, colors and holes are accepted.

Features

- Highly Performance heatsinks.

- Light and highly conductive thermal dissipation.

- Available in various dimensions and shapes.

- Customized lengths, colors and holes are accepted.

- Applied heat pipe, aluminum / copper stacked fin, or aluminum extruded / die-casting parts.

- With complex fin structure, easily shaped, and applied to different thermal requirements.

- Available in coating thermal adhesive / pad.

Material

6061 / 6063

Main Processing

CNC Milling → Stamping → Drilling → Tapping

Surface Treatment

Hairline Process / Sand-Blasting or Abrasive / Anodizing / Ultrasonic Cleaning / Vibrating Finishing.

Other Process

Riveting or Clinching.

Thermal Adhesive or Thermal Grease.

- Photo Gallery

Having trouble dealing with aluminum manufacturing?

Contact us and we will provide solutions.

More DetailsWhy Are Precision-Engineered Heatsinks Critical for Your Next-Generation Electronic Products?

As electronic components become more powerful and compact, effective thermal management becomes increasingly critical. Han Chang's custom heatsinks are precision-engineered with your exact specifications in mind, from complex fin structures to specialized surface treatments. Our comprehensive manufacturing capabilities—including CNC milling, stamping, drilling, and anodizing—ensure that every heatsink perfectly addresses your product's unique thermal challenges. Partner with us to develop cooling solutions that enhance reliability, improve performance, and differentiate your products in the marketplace.

Our comprehensive manufacturing process includes CNC milling, stamping, drilling, and tapping, followed by meticulous surface treatments including hairline processing, sand-blasting, anodizing, ultrasonic cleaning, and vibrating finishing. The heatsinks can be enhanced with heat pipes, aluminum/copper stacked fins, or specialized die-casting techniques to address complex thermal challenges. Additional options include thermal adhesive or grease application, riveting, and clinching services, providing complete thermal management solutions for your most demanding electronic cooling requirements.