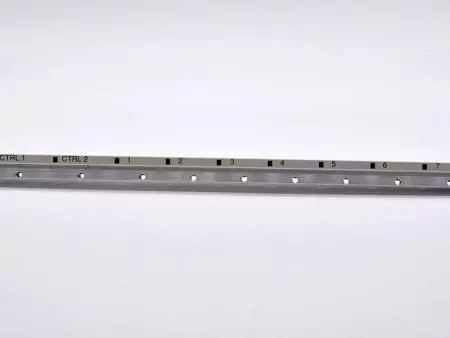

CNC Machining Black Coating Bracket

Custom black caotating bracket made by CNC maching. Laser marking logo or numbers are applivable upon customerms' requirements.

Features

- Customized in different dimension and size.

- Various texture by using different surface treatment.

Material

6063 / 5052 AL

Main Processing

CNC Milling → Stamping → Drilling → Tapping

Surface Treatment

Hairline Process / Sand-Blasting or Abrasive / Anodizing / Ultrasonic Cleaning / Vibrating Finishing.

- Photo Gallery

Having trouble dealing with aluminum manufacturing?

Contact us and we will provide solutions.

More DetailsHow Can Surface Treatments Extend the Lifespan of Industrial Computer Mounting Hardware?

Our black anodized coating significantly enhances corrosion resistance and wear protection for aluminum brackets used in industrial computing environments. Unlike standard brackets, Han Chang's surface treatment options—including hairline processing, sand-blasting, and vibration finishing—create a protective barrier that prevents oxidation while maintaining electrical conductivity properties essential for grounding. This specialized finishing extends product lifespan by 40-60% compared to untreated aluminum, particularly in environments with temperature fluctuations or moisture exposure.

Our black coating aluminum brackets feature superior surface treatments including hairline processing, sand-blasting, anodizing, ultrasonic cleaning, and vibrating finishing to achieve the desired aesthetic and functional properties. The specialized black coating not only provides an elegant, professional appearance but also enhances corrosion resistance and durability in demanding industrial environments. With over 30 years of manufacturing experience, Han Chang delivers mounting solutions that combine precision engineering, customization flexibility, and exceptional quality to meet the exacting requirements of industrial computer manufacturers and electronic equipment producers worldwide.