Aluminium machining

CNC machining and frabricating

CNC machining (milling) is a precision manufacturing method commonly employed in conjunction with aluminum extrusion processes. It utilizes Computer Numerical Control (CNC) systems to precisely control the movement of cutting tools on workpieces. This enables the creation of aluminum components with intricate designs and precise dimensions. Below is an explanation of the CNC milling process:

Aluminium CNC Machining

Our team has rich experience of CNC machining. By using different processing technic suchas 4-axis processing, Vacuum cup processing to manufacture more efficient but alsoprovide special effects on the work pieces like mirror finish. We are able to producehigh quality aluminum products like IPC chassis, aluminum componentsand aluminum frames.... etc. With the development of industrial 4.0, the demands of industrial computers are increasing, therefore,we constantly updating our machine forhigher functionality and better precision to make customers' satisfaction.

1. Design and Programming:

.Firstly, machining plans are formulated based on product design CAD drawings or 3D models to determine the required dimensions, shapes, and surface features of the workpiece.

.Subsequently, the machining plans are translated into CNC code, such as G-code or other machine languages, which includes machining parameters such as tool paths, cutting speeds, and feed rates.

2. Material Preparation:

.Suitable machining materials, such as aluminum alloys, copper, etc., are selected.

.The material is secured onto the worktable of the CNC milling machine, often using fixtures, bolts, or vacuum suction, to ensure stability during the machining process.

3. CNC Machining Process:

.Pre-programmed machining operations are loaded.

.The CNC system controls the movement and rotation of the tooling according to the program, performing cutting, carving, and hole drilling operations along predetermined paths on the workpiece.

.During the machining process, the CNC system monitors the positions of the tooling and workpiece in real-time to ensure machining accuracy and quality.

4. Post-Machining Finishing:

.Upon completion of machining, necessary post-processing activities are carried out on the workpiece, such as deburring, surface polishing, and cleaning, to ensure the final product's appearance and quality.

5. Inspection and Quality Control:

.Inspection and measurements of workpiece dimensions, surface roughness, etc., are conducted to ensure compliance with design requirements and quality standards.

.Necessary adjustments and corrections are made based on inspection results to enhance production efficiency and product quality.

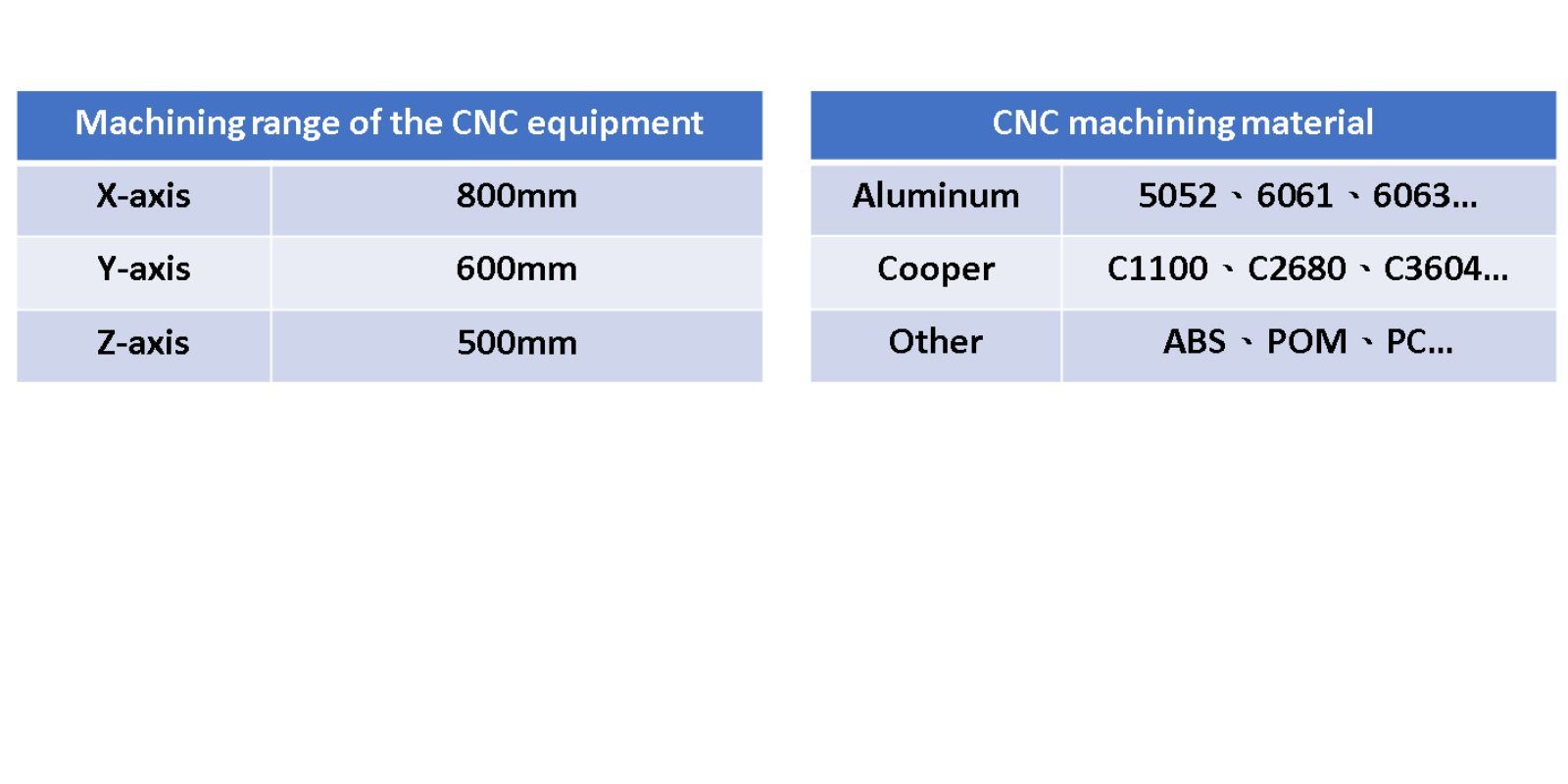

Workpiece dimensions and extrusion tolerance.

CNC milling process offers high levels of automation and precision, making it suitable for manufacturing parts of various sizes and shapes, widely used in industries such as aerospace, automotive, medical devices, electronics, etc.Common materials used in CNC machining and their machining dimension ranges are as follows:

- Related product

CNC machining black anodized heatsinks

CNC machining black anodized heatsink , mainly used for motherboard. The grooved design of the surface increasing the dissipation area. Customized lengths,...

DetailsBlack anodizd embedded chassis

Black anodized embedded system case made by CNC milling and stamping. Aluminum alloy has high thermal conductivity and heat dissipation. We also provide...

DetailsCNC machinig ditched silver anodized heatsinks

Mainly used for the motherboard, the grooved design can increase the heat dissipation area.

DetailsH shaped heatsinks

CNC machining H shaped silver anodized heatsink, light and highly conductive thermal dissipation. Customized lengths, colors and holes are accepted.

DetailsCNC machining gray anodized heatsinks with abbrasive.

Using CNC machining to ensure the flatness of the intersurface. External surface treatment like abbrasive and anodizing is applied to the product if the parts...

DetailsGray assembled embedded chassis

This chassis can be disassembled into top cover, bottom plate, front and rear panels. Customize made exclusive chassis according to the requirments.

Details