Sheet metal fabricating

aluminum/zinc‑plated steel sheet

Sheet Metal fabrication encompasses a range of processes aimed at transforming flat sheets of metal into various shapes and structures. This versatile manufacturing technique involves cutting, bending, punching, and assembling metal sheets to create components or products tailored to specific requirements. One common method within sheet metal fabrication is laser cutting, which utilizes a high-powered laser beam to precisely cut through metal sheets, offering exceptional accuracy and flexibility in design. Another technique is metal bending, where metal sheets are formed into desired shapes using specialized equipment such as press brakes or rollers. Additionally, processes like punching and stamping are employed to create holes, patterns, or intricate details on the metal surface.

Sheet metal working

In addition to CNC machining, we are also specialized in sheet metal fabrication, which is the process of forming a piece of metal into a desired shape through bending, stretching, and removal of material. Typical sheet metal parts we manufacture include enclosures, chassis, brackets, assemblies, cabinets, and other components. Sheet metal parts are known for their durability and low cost, which makes them great for end-use applications like enclosures or chassis.

1. Design and Planning:

.Initially, based on product design CAD drawings or 3D models, a processing plan is formulated to determine the required dimensions, shapes, and surface characteristics of the workpiece.

2. Material Selection:

.Different types of metals such as steel, aluminum, copper, or stainless steel are chosen according to project requirements.

3. Cutting:

.Sheet Metal Cutting: Various cutting methods like NCT, laser cutting, or punching are employed to cut the metal sheet into the desired size and shape.

4. Forming and Shaping:

.Bending: Utilizing a press brake, bends, angles, and curves are created based on design specifications.

.Punching: During the punching process, molds and punches are used to punch the metal sheet, creating the desired shapes, holes, or textures.

5. Welding and Assembly:

.Welding: Welding techniques are used to join metal pieces together.

.Riveting: Metal sheets are riveted together through pre-drilled holes and then secured in place.

6. Surface Treatment:

.Deburring: Sharp edges and burrs are removed from metal components after forming and assembly to ensure safety and aesthetics.

.Surface Treatment: Metal surfaces may undergo treatments such as coatings, painting, or surface finishing to enhance appearance, durability, and corrosion resistance.

Workpiece dimensions and extrusion tolerance.

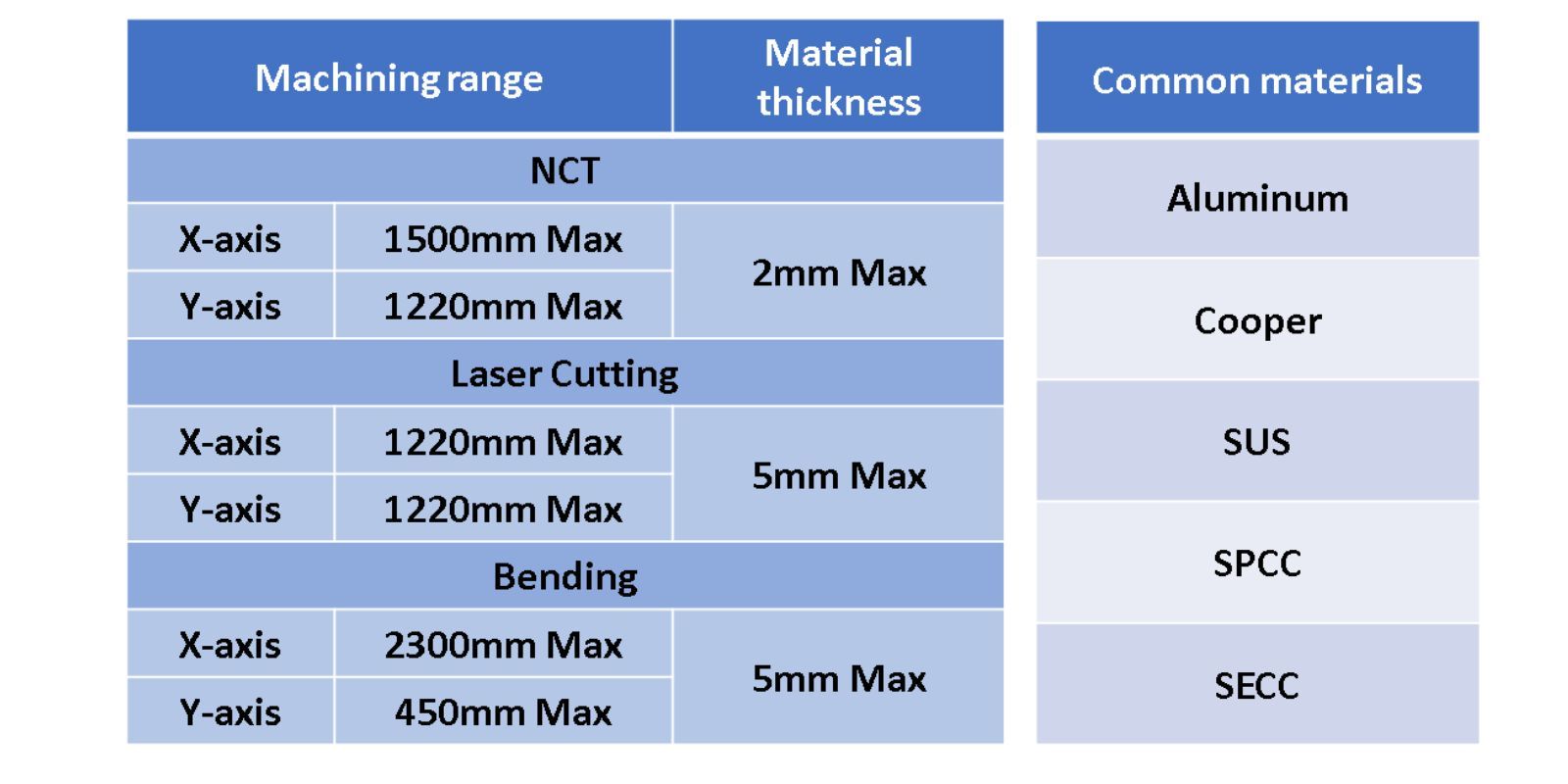

Sheet metal fabrication is a versatile manufacturing process widely used in industries such as automotive, aerospace, construction, electronics, and manufacturing. Common materials used in NCT and their machining dimension ranges are as follows: