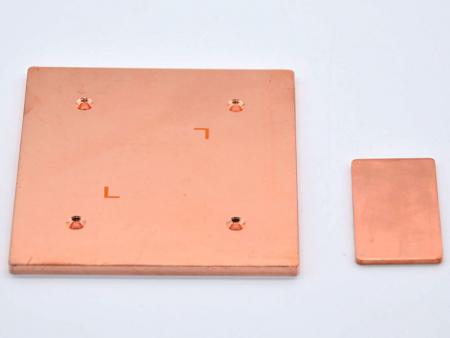

Copper Blocks

Thermal dissipation copper block

CNC milling copper block which can be install on the chassis for better heat dissipation. Customized different dimension depnons the requirments.

Features

- Light and highly conductive thermal dissipation.

- Available in various dimensions and shapes.

- Customized lengths, colors and holes are accepted.

- Applied to different thermal requirements.

- Available in coating thermal adhesive / pad.

Material

6061 / 6063

CU

Main Processing

CNC Milling → Stamping → Drilling → Tapping

Surface Treatment

Hairline Process / Sand-Blasting or Abrasive / Anodizing / Ultrasonic Cleaning / Vibrating Finishing.

Other Process

Thermal Adhesive or Thermal Grease.

- Photo Gallery

Having trouble dealing with aluminum manufacturing?

Contact us and we will provide solutions.

More DetailsHow can copper blocks improve thermal efficiency in compact electronic systems?

Copper's thermal conductivity is approximately 60% higher than aluminum, making our precision-engineered copper blocks ideal for compact, high-performance electronic systems where heat dissipation is critical. Our customizable dimensions and mounting options allow for optimal thermal transfer in space-constrained applications, reducing operating temperatures by up to 30% compared to traditional solutions. Contact us to discuss your specific thermal management requirements.

Our copper blocks feature exceptional thermal conductivity properties that significantly outperform aluminum alternatives in applications where maximum heat transfer is essential. Available with various surface treatments and thermal interface options including adhesives and thermal pads, these components integrate seamlessly into your thermal management system. Han Chang's 30 years of manufacturing expertise ensures each copper block meets precise specifications while providing the reliability and performance required for mission-critical electronic cooling applications.